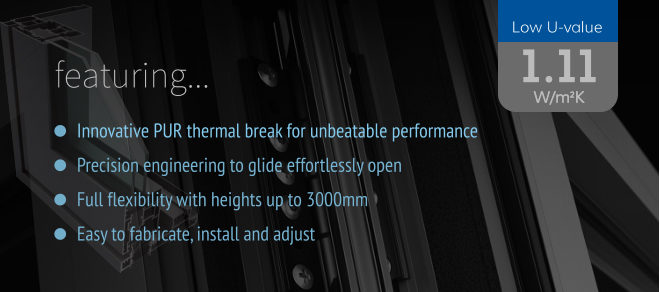

The PURe® SLIDE high performance aluminium door range features our innovative patented expanded polyurethane (PUR) thermal barrier, allowing ultra-low U values to be achieved.

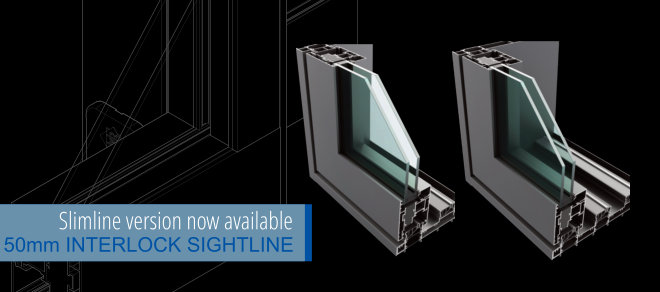

Both inline slide and lift & slide configurations are also available as a slimline version (PURe® SLIDE SL) with a 50mm interlock sightline for uninterrupted views, whilst the heavy-duty Lift & Slide option allows leaf weights up to 300Kg.

All doors are available pre-finished in an almost unlimited range of colours and finishes both inside and out, in heights up to 3m and are easy to fabricate, install and adjust.

Thermal Performance

U-values as low as 0.95 W/m2k when calculated as a CEN Standard triple glazed door.

Sizes

Typical* sizes

| Max Door Leaf Width | 3005mm |

| Max Door Leaf Height | 2916mm |

| Max Outerframe Width | Project specific |

| Max Outerframe Height | 3000mm |

| Max Weight Per Door Leaf (Inline Standard Duty) | 160Kg |

| Max Weight Per Door Leaf (Lift & Slide Standard Duty) | 200Kg |

| Max Weight Per Door Leaf (Lift & Slide Heavy Duty) | 300Kg |

*For guidance only – when exceeded please consult our technical department on 01709 772600

Glazing

28mm - 52mm

For thicker options please consult our technical department

Weather Performance

Tested to BS6375-1 and BS6375-2

Security

Security tested to PAS24: 2016, security hardware required. Q-Mark fully certified. Secured by Design accreditation.

Construction

- Unique jointing method of head and sill allows thermal breaks to always line through with door sash for thermal efficiency

- Adjustable locking points for easy locking and weatherproof seal

- Choice of chamfered or square beads, or Mix and Match

- All hardware is securely fixed into the aluminium profiles, not the thermal break, to avoid thermal bridging and provide a more secure fixing

- Simple drainage option allows cill to be dropped down to give a lower threshold for easy access

- Backer rod and EPS insert available for improved thermal performance

- High tech roller design for years of trouble-free operation

Fabrication and Installation

- Same sight lines and sections for inline sliding and standard duty lift & slide doors

- Constructed using mitred corners with alignment chevrons to assist in clean, accurate mitres

- No need for complicated drainage preps to outerframe track

- Mechanical corner cleats for ease of fabrication

- Punch tool available for help in fabrication

- Adjustable locking points and rollers for quick and easy installation

- Delivery in 3 working days for stocked single colour profiles (anthracite grey and hipca white)

| Inline Slide | Lift & Slide | Single Track | Double Track | Triple Track | |

| Standard | Heavy Duty | ||||

| Slimline | Inline only |

Further Product Resources

PURe® SLIDE inline slide Datasheet

To include in your tender submissions

Download (PDF Document | 726 KB)

PURe® SLIDE lift & slide Datasheet

To include in your tender submissions

Download (PDF Document | 696 KB)

Operations and Maintenance Manual

For window, door and curtain wall systems

Download (PDF Document | 577 KB)