With sustainability targets rising across the fenestration sector, product manufacturers, and specifically the technical documents they provide, have an vital role to play. In our latest blog, Luke Osborne, Senior Architectural Systems’ UK sustainability lead, discusses the importance of transparent and trustworthy EPDs.

When it comes to making claims about the performance of a product, Environmental Product Declarations, or EPDs, are a vital part of cutting through the noise and proving how ‘environmentally-friendly’ a product really is. For installers and fabricators, understanding what an EPD is, and what makes one truly useful, is key to being able to have more informed discussions with main contractors and specifiers. As regulations and sustainability targets tighten and carbon reporting becomes more project-specific, this ability to interpret and apply environmental data is no longer just a technical concern but can also be a commercial advantage.

What is an EPD?

Put simply, an EPD is a third-party verified document that outlines the environmental impact of a product across its entire life cycle. This includes everything from raw material extraction and manufacturing to transportation, installation and end-of-life disposal. It doesn’t make value judgments about whether a product is sustainable, but it does provide the facts needed to make meaningful comparisons and informed decisions.

Not all EPDS are equal

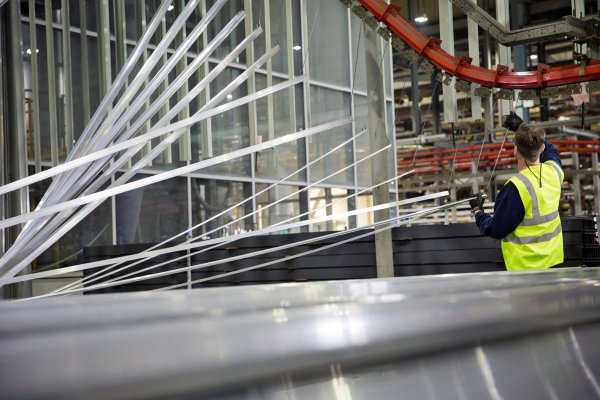

Senior Architectural Systems has recently published a new EPD for its SF52 mullion drained aluminium curtain wall system, and by doing so we hope to have set a new benchmark for transparency in the fenestration industry. Developed in accordance with EN 15804+A2 and independently verified to ISO 14025:2011, our SF52 EPD includes data on global warming potential, energy consumption and water usage but crucially, it covers the full system—not just the aluminium billet. That means thermal breaks, gaskets, fixings, fabrication and delivery to site are all accounted for, along with the energy-intensive extrusion process.

This level of detail is often missing from comparable EPDs, which typically report carbon figures for 1kg of aluminium and exclude key stages of the product’s journey. By contrast, we have created an EPD that offers project-relevant data which actually reflects the reality of what contractors are working with on site.

The devil is in the detail

Curtain walling is inherently bespoke, with individual project requirements introducing design changes which makes like-for-like comparisons of different systems very difficult. That’s why we have aligned our EPD with the latest BS EN 18001:2024+A2 Product Category Rules for curtain walling, using the recommended reference sizes for the system. Importantly, this means that glazing is left out, as it is not normally supplied by system houses. If glazing is included, it can distort results when divided down to 1m² declared unit. The heavy weight of glass, combined with its relatively low carbon per kg, makes the overall figures for the aluminium system look lower than they really are after conversion. That’s why for complete accuracy, glazing should always be reported separately through its own EPD.

By taking this approach, we believe our SF52 EPD gives a true and transparent figure per m2 of aluminium system. In addition, multiple system sizes have been verified and scaling tables developed to ensure precise data is available across the full SF52 range, and we are proud that we are currently the only UK system house to take this comprehensive approach.

Why it matters to you

Reliable environmental data has become a vital part of the construction process. Whether you’re quoting for a BREEAM-certified build or advising on Passivhaus compliance, having access to clear, project-specific data helps strengthen your position within the supply chain, support sustainable specification, and stand out in competitive tenders. Our SF52 curtain wall system is one of our most popular product solutions so it made sense to us to lead with this EPD but we are in the progress of developing further EPDs for our aluminium system portfolio, including our patented PURe® range of windows and doors. It’s all part of our commitment to raising standards and helping to drive continuous improvement in environmental performance across the aluminium fenestration industry.

Download the SF52 EPD via Senior’s NBS Source profile or request a copy from UK sustainability lead Luke Osborne at lukeo@sasmail.co.uk.

Comments are closed.