Have you ever had a romantic meal ruined because it’s too noisy for conversation? Or tossed and turned all night in your hotel room because of the busy main road outside? If so, you’ll know just how important acoustics are for every building whether residential or commercial. Here we reveal our top ten tips to help architects get the acoustics right.

-

Consider acoustics right at the start

It costs much more to fix the acoustics of a building once it is completed, so make sure acoustics is part of the planning stage of your projects and think about consulting a suitably qualified acoustician to avoid any expensive mistakes. Remember to design for the ears as much as for the eyes and think about how the building will be used and by whom. Poor acoustics and sound pollution can reduce the quality of life for those using the building, causing stress and affecting health, social behaviour and productivity.

Example: The Hilton Garden Inn Hotel

The Hilton Garden Inn Hotel

The Hilton Garden Inn overlooks the Lancashire Cricket pitch at Emirates Old Trafford. Careful consideration was given to the acoustic performance of the glazing package, particularly on the front elevation of the hotel which is located close to a main road. To further enhance the comfort of the hotel’s guests, Senior’s innovative PURe® SLIDE doors were specified for their exceptional low U-values and improved thermal efficiency.

-

Remember the regulations

The main regulations you need to consider are ‘Part E of the Building Regulations, Resistance to the passage of sound1’. This covers sound insulation requirements in dwelling-houses, flats, rooms for residential use and schools. The government has also issued additional guidelines for schools (‘BB93: acoustic design of schools - performance standards’2).

The Building Regulations generally do not cover hospitals, public or commercial buildings, although there are several guidelines that can help with specification. For example, the government has issued guidance on acoustic requirements to help those involved in the development of healthcare facilities (‘Space for Health: Healthcare Environment 4032:0.3: England Acoustics: Technical design manual’3 and Specialist Services Health Technical Memorandum 08-01: Acoustics’4) and the British Council for Offices has published it’s BCO Guide to Specification 20195 with recommendations for office developments across the UK. Unless the building is for residential use then ‘The Control of Noise at Work Regulations 20056’ will also apply.

-

Determine the source of noise pollution

Before thinking about how to reduce noise pollution, you need to discover the source, intensity and frequency of the sounds. For example, road traffic noise, especially lorries, tends to be low frequency with volume levels for a diesel truck at 50 ft of 90 dB. Jet aircraft engines have higher frequency noises and volumes 1000 ft under the flight path can reach up to 100 dB7. The human ear is more sensitive to high frequency sounds and so sound measurements are often weighted to take this into account, denoted as dBA. Understanding the source of the noise will help in the selection of insulating materials. It is often harder to counteract the frequency of the noise pollution than the volume.

Example: The Hilton Hotel, Heathrow Terminal 5

Hilton Hotel Heathrow Terminal

Situated close to Heathrow’s Terminal 5 building, the hotel features Senior’s SPW600 75mm deep thermally broken casement system to achieve maximum noise isolation from aircraft flying directly overhead.

-

Choose materials carefully

The look, feel and thermal performance of the materials you choose are important, but remember to consider their acoustic qualities as well. Think about sound reflections from straight surfaces which can affect clarity of sound in internal spaces and hamper communication. Make sure the materials you choose absorb the right sound frequencies for the location and use.

-

Concentrate on the fenestration

Whilst the acoustic performance of a building is dependent on the materials used, one of the biggest factors in sound ingress is the number and type of openings in the building envelope. In other words, the windows and doors. In theory the fewer openings, the better the sound proofing, but in practice daylight, ventilation and easy exit from the building are usually more important. No-one wants to work or live in a windowless room! However, specifying the right fenestration can have a huge impact on sound proofing any building.

-

Focus on the frames

Ali Vu windows

Although timber is a good absorber of sound waves, cost and high maintenance mean that wooden frames are often not first choice. This is especially true for commercial buildings, but increasingly so for domestic applications too. If you decide on an aluminium frame, not only do they require very little maintenance, but they are also strong, durable and 100% recyclable. From a sound proofing point of view this means that the frames can be incredibly slim, giving very little surface area through which sound waves can travel. Take, for example, our Ali VU windows which have impressively slim frames to help maximise daylight.

-

Think about the thermal break

Of course, aluminium windows aren’t solid, but sound waves can travel through both the aluminium and the air between the inner and outer aluminium profiles. These days, most aluminium windows have a thermal break to prevent the loss of heat across the frame, but these can also act as acoustic breaks to help prevent sound waves passing through the frame as well. The most common is the polyamide thermal break, which is mechanically locked into aluminium window framing, and is around a thousand times less conductive than the surrounding aluminium.8

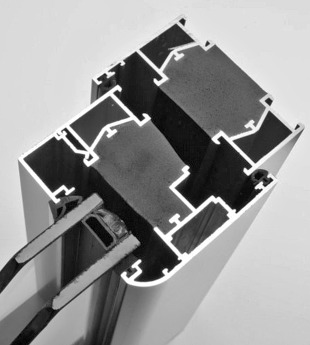

Cross section of PURe® window showing the innovative PUR thermal break which fills the entire cavity between the internal and external aluminium profiles

But not all thermal breaks are equal. In a bid to produce ever more energy efficient windows, manufacturers have developed new ways of preventing both heat and sound from travelling through aluminium window frames. Amongst the most innovative of these is our patented PURe® window and door system, which uses expanded polyurethane (PUR) foam as a thermal break filling the entire cavity between the internal and external aluminium profiles.

Not only is polyurethane foam good at preventing the conduction of heat, but it is also an excellent sound absorber often used in soundproofing products9,10. The sound waves can’t pass directly through the thermal break but instead are forced to change directions many times as they pass through the PUR foam. Each time the sound wave changes direction some of its energy is absorbed which reduces the amount of sound you can hear, giving these frames exceptional acoustic properties. Just one of the reasons that Simon Crowe, Director at Niven Architects chose PURe® windows for the Premier Inn adjacent to the busy Darlington Ring Road.

-

Weigh up the glass

The acoustic performance of the glazing depends on: the thickness of the glass, the number of pieces of glass (single, double or triple glazed) and the thickness of the air cavity. Generally thicker glass, more pieces and wider air cavities mean better acoustics. But it’s not quite that simple. That’s because each type and thickness of glass will have its own coincidence frequency, where the sound rather than being dampened will instead be amplified. These so called ‘frequency holes’ can be plugged by using glass of different thicknesses, for example a double-glazed unit with a 4mm pane and a 6mm pane can perform better than one with 2x6mm panes at certain frequencies. Even better acoustic performance can be achieved by using PVB (polyvinyl butyral) or resin acoustic interlayers, which offer sound insulation against high intensity, low frequency traffic noise. Specialist acoustic glass products are also available to meet specific sound proofing criteria.

-

Select for seals

The final part of the jigsaw is the airtightness of the window. If air can pass through the window, so can the sound. So, when selecting a window look at both the design and the air tightness ratings and think carefully about whether trickle vents need to be included. Always check that the window has been rigorously tested for air tightness. At Senior we use only the best quality gaskets to ensure an air tight seal. Air tightness test results for individual products can be found on our website.

-

Inspect the installation

Quoted sound reduction figures mean nothing unless the windows and doors have been properly installed. A badly fitted window with gaps between the frame and the wall can undo all your efforts to reduce the ingress of noise from the outside. Always choose a reputable installer with the correct training and inspect the work at regular intervals.

These top 10 tips give you just a quick overview of the important things to consider when specifying glazing systems to reduce noise pollution. The frame, the glass and the design can all have a significant impact on acoustics.

However, acoustics is a vast and complex subject and we haven’t even mentioned curtain walling yet! So if you would like more information and advice on how our products can help you comply with particular acoustic specifications, please contact one of our architectural advisors. They have a wealth of experience at helping architects to specify and detail glazing systems for a host of applications.

References:

- https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/468870/ADE_LOCKED.pdf

- https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/400784/BB93_February_2015.pdf

- https://www.thenbs.com/PublicationIndex/documents/details?Pub=DH&DocID=298222

- https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/144248/HTM_08-01.pdf

- https://www.bco.org.uk/Research/Publications/BCOGuideToSpec2019.aspx

- http://www.legislation.gov.uk/uksi/2005/1643/contents/made

- https://www.roads.maryland.gov/mdotsha/pages/index.aspx?PageId=827

- https://muller.ch/html/thermal-break.html

- https://en.wikipedia.org/wiki/Acoustic_foam

- https://www.acousticalsurfaces.com/foam_stop/poly_sw.htm

Comments are closed.