At the end of last year, the government opened its consultation on the proposed Future Homes Standard for new build homes ahead of its planned introduction in 2025. With the industry still getting to grips with meeting the stricter Part L targets, it’s never been more important to future-proof your thinking when it comes to aluminium windows, doors and curtain wall systems. In our latest blog, we take a look at some of the key challenges – and opportunities – that 2024 has in store.

It’s fair to say that the future of the Future Homes Standard is far from clear, but as the 12 week consultation nears its completion on 6th March, more will be revealed and hopefully understood. What we can take as a given though is that energy-efficiency targets will only get stricter and this puts the focus not only on the availability of sustainable building materials, but also on the environmental credentials of the companies that make them.

Don’t make fabric first an after thought

Although in its current form, the Future Homes Standard seems to be placing more emphasis on ‘green’ and renewable energy sources such as solar PV panels and heat source pumps, the importance of creating homes that reduce heat loss is still an important consideration – and thermally-efficient aluminium windows and doors have a vital role to play.

As any new targets are likely to build on what has already been introduced with the 2022 updates to Part L of the Building Regulations, we should be looking to exceed rather than just meet these current U-values. We have developed a wide range of compliant aluminium windows and doors, including our patented PURe® aluminium window that can achieve U-values of 0.71 W/m2K when calculated as a CEN commercial window and we are constantly looking at ways to bring more innovation and choice to our customers. This includes offering a fully compatible range of windows, doors and curtain wall systems that together can provide a more holistic approach to the ‘fabric first’ method of building design. After all, whether a building’s heat source is traditional or renewable, ‘green’ energy will escape just as quickly through a poorly insulated home so getting the fenestration right is a must.

Retrofit means business

Of course it’s not just about new builds – there is lots of work to be done to improve the energy efficiency of existing housing and commercial building stock. The retrofit market is definitely one to watch, with the government announcing a new wave of funding and recommendations to improve the energy-efficiency of existing properties.

Replacing old and draughty windows is an essential part of this, so it’s good to know that all our aluminium windows can be installed with double or triple-glazed glass to enhance the thermal-performance of the frame. We also offer full product training and a range of support service to all our fabricators and installers to help identify the most effective solutions for retrofit projects. As a privately owned manufacturer, we are also in complete control of the production of our products so we can support large and long term contracts.

For heritage and period properties that require a more modern solution, we can also offer a number of stylish fenestration systems, including our Ali VU window. This slim framed heritage style window is not only Part L compliant but is also ideally suited for projects in conservation areas where planning restrictions may apply. We are excited to soon add a new heritage door to our range and more details on this will be available very soon!

Sustainability in the supply chain

Another conservation that is set to continue into 2024 and beyond is the very important issue of supply chain sustainability and in particular, the need to have a greater awareness of how much carbon is generated through the manufacture, delivery, installation and disposal of specified building materials. We appreciate that for any product to be truly sustainable, it’s not just about how well it performs when installed. After all, if an aluminium window system achieves low U-values but this is at the cost of an energy-intensive manufacturing process or a large carbon footprint being created through its transportation from an overseas manufacturer, the overall picture might not be as green as first thought.

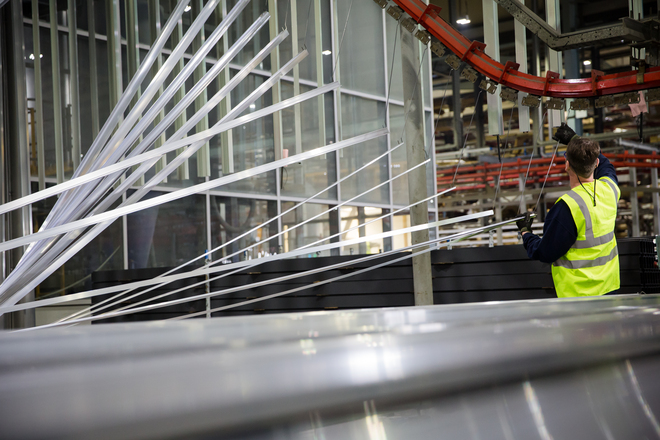

We have put sustainability at the heart of our business operations, from ensuring that we only use ethically sourced and recycled aluminium in all our extrusions, to continuously investing in our UK based manufacturing facility and distribution centre to reduce the environmental impact our business operations.

Flexibility going forwards

From investing in our manufacturing capabilities to ensuring that we can offer a wide range of low carbon and thermally-efficient compliant aluminium, we are ready to help all our customers navigate the challenges and opportunities that lay ahead.

To discuss how we can help support you, please get in touch with us today.

Comments are closed.